Marvelous Tips About Can You Splice Two Cables Together

Can You Splice Two Cables Together? Let's Get Wired!

1. Understanding the Basics of Cable Splicing

So, you're staring at two severed cables, maybe from a rogue weed whacker incident (we've all been there!), and you're wondering, "Can you splice two cables together?" The short answer? Yes, you generally can. But, and this is a big but, doing it correctly is crucial. We're talking safety here, not just about getting your Netflix back up and running.

Think of it like performing surgery. A bad splice is like a botched operation — it can lead to bigger problems down the line. A secure connection ensures proper signal or power flow. A weak or poorly insulated splice, on the other hand, becomes a fire hazard or a source of frustrating intermittent issues. Not fun.

We need to be honest though, not all cables are created equal. Some are easier and safer to splice than others. Low-voltage wiring, like speaker wire or some types of network cables, is generally more forgiving than high-voltage electrical wiring. Before you even think about touching those wires, know what you're dealing with. When in doubt, call a professional.

Ultimately, splicing cables correctly is about respecting electricity and understanding the inherent dangers. Don't dive in headfirst. Do your homework. And always, always, always turn off the power before you start messing around with any electrical wiring. Seriously.

2. Choosing the Right Tools and Materials

Alright, so you've decided to take on the cable-splicing challenge. Awesome! But before you grab any old pair of pliers, let's talk about the right tools and materials. Using the correct equipment can make the job easier, safer, and ultimately more effective. Think of it like cooking; you wouldn't try to bake a cake with a hammer, would you?

First up: wire strippers. These are essential for cleanly removing the insulation without damaging the conductor itself. A damaged conductor can weaken the connection and cause problems down the line. Next, consider your connectors. Butt connectors, crimp connectors, and even solder are all viable options, depending on the type of cable you're working with. Each has its own pros and cons, so do a bit of research to see what works best for your application. Heat shrink tubing is your best friend for sealing the splice and providing insulation. It shrinks tightly around the connection when heated, creating a weatherproof and durable seal.

Beyond that, a good pair of lineman's pliers is invaluable for twisting wires together securely. A multimeter is helpful for testing the connection after you're done, ensuring that everything is working correctly. And, of course, safety glasses and insulated gloves are a must. Electricity and metal shards are not a good combination for your eyes and hands.

Don't skimp on quality when it comes to your tools and materials. Cheap tools can break easily, and low-quality connectors can lead to unreliable connections. Invest in good equipment, and it will pay for itself in the long run. Just like any other DIY task, having the right tools for cable splicing and electrical work is the recipe for success.

3. Step-by-Step Guide to Splicing Cables Safely

Okay, let's get to the nitty... err, details of actually splicing those cables together. Remember, safety first! Turn off the power at the breaker box before you even think about touching the wires. Double-check with a multimeter to be absolutely sure. No shame in triple-checking, honestly.

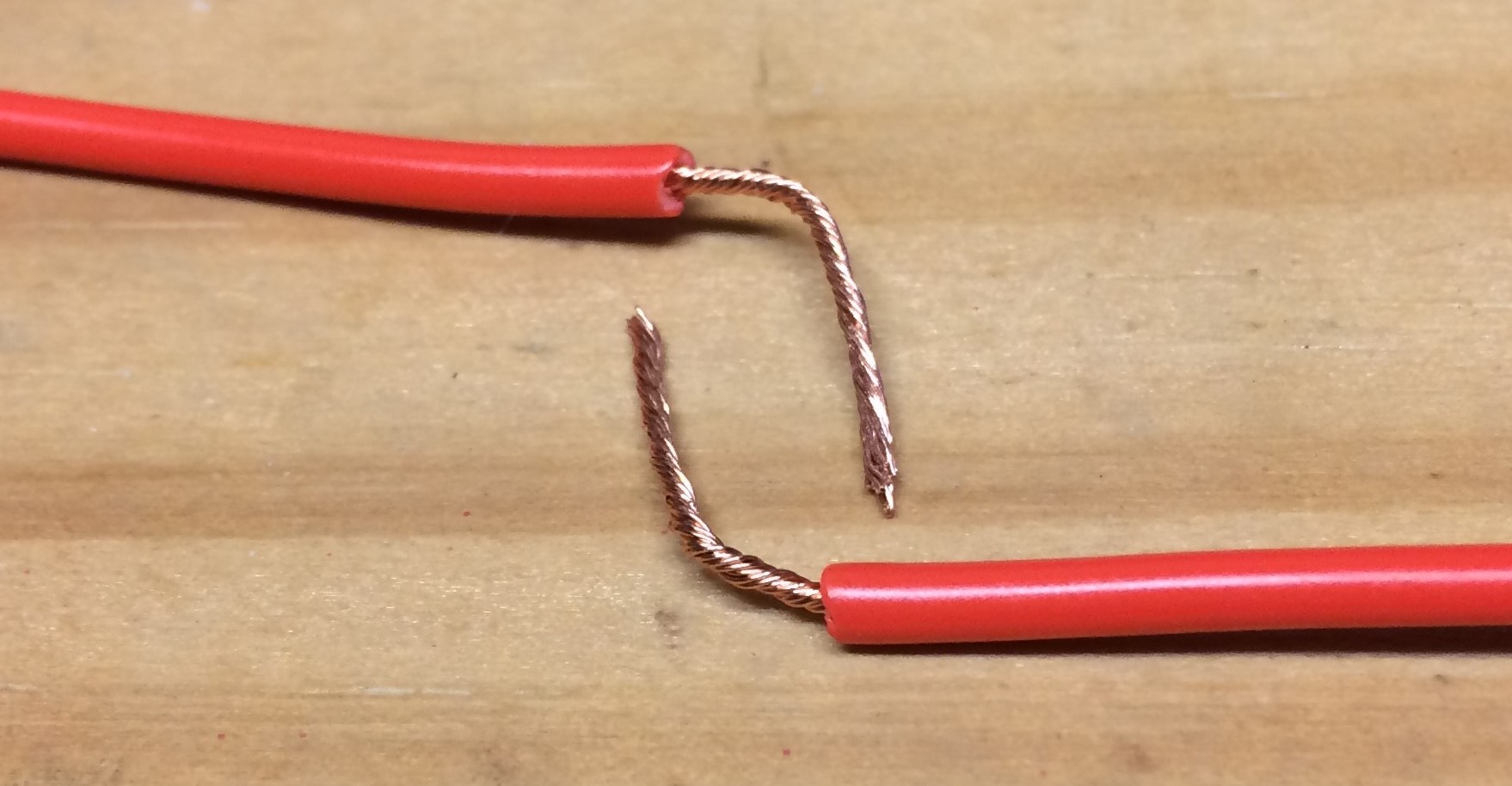

Start by stripping the insulation from both ends of the cables you want to splice. Use your wire strippers to carefully remove the outer jacket and the insulation from each individual wire. Be careful not to nick or damage the conductors. A clean strip is a happy strip. Next, twist the exposed conductors together tightly. If you're using crimp connectors, insert the twisted wires into the connector and crimp it securely with your crimping tool. Make sure the crimp is tight and the connector is securely attached.

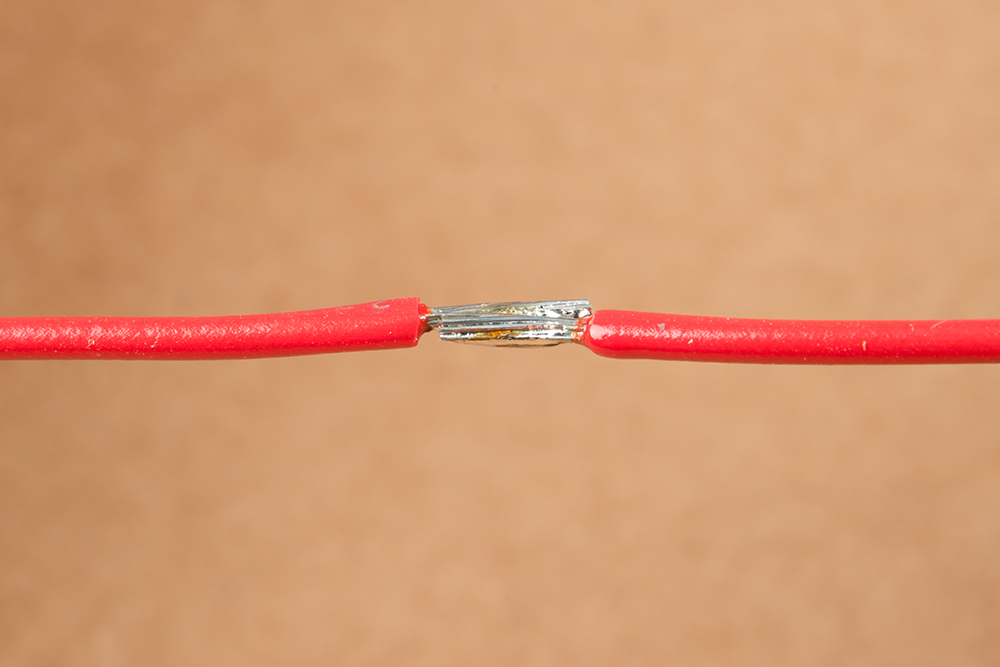

If you're soldering, heat the twisted wires with a soldering iron and apply solder to create a strong, conductive bond. Be careful not to use too much solder, as this can create a brittle connection. Now, this is crucial, slide heat shrink tubing over the splice and heat it with a heat gun (or a lighter, carefully!) until it shrinks tightly around the connection. This will provide insulation and protect the splice from moisture and corrosion.

Finally, gently tug on the splice to make sure it's secure. If anything feels loose or wobbly, redo it. There's no point in having a splice that will fail at the first sign of trouble. Once you're confident that the splice is secure, you can turn the power back on and test the connection. If everything works, congratulations! You've successfully spliced two cables together.

4. Common Mistakes to Avoid When Splicing Cables

Even with the best intentions and the right tools, it's easy to make mistakes when splicing cables. Let's be honest, we've all been there. So, to help you avoid some common pitfalls, here are a few things to watch out for. Ignoring safety precautions is number one on the list. We can't stress this enough: always turn off the power before working on electrical wiring. Don't take shortcuts. Your life isn't worth saving a few minutes.

Using the wrong type of connectors is another common mistake. Not all connectors are created equal, and using the wrong one can lead to a weak or unreliable connection. Make sure you're using connectors that are rated for the type of cable you're working with. Improper stripping of insulation can also cause problems. If you strip too much insulation, you'll leave exposed conductors that can short circuit. If you don't strip enough, you'll have a poor connection. Get the stripping just right. Not applying enough heat shrink tubing, or not heating it properly, can leave the splice exposed to moisture and corrosion.

Another problem can be rushing the job. Take your time and be methodical. Don't try to rush through the process, or you're more likely to make mistakes. And speaking of mistakes, never assume anything. If you're not sure about something, ask for help from a qualified electrician. It's always better to be safe than sorry.

In addition, be aware that splicing certain types of cables (especially high-voltage ones) is best left to professionals. If you're not comfortable working with electricity, don't hesitate to call an electrician. They have the training and experience to do the job safely and correctly.

5. When Should You Call a Professional?

Let's face it, sometimes DIY projects are best left to the experts. Splicing cables, especially when dealing with high-voltage wiring or complex electrical systems, definitely falls into that category. Knowing when to call a professional electrician can save you time, money, and potentially even your life.

If you're working with high-voltage wiring (think anything that connects directly to your home's electrical panel), it's always best to call a professional. High voltage can be extremely dangerous, and even a small mistake can have serious consequences. Additionally, if you're not comfortable working with electricity, or if you're unsure about any part of the process, don't hesitate to call an electrician. It's better to be safe than sorry. Complex wiring systems, such as those found in older homes or commercial buildings, can be tricky to work with. If you're dealing with a complex system, it's best to leave it to the professionals.

Moreover, if you're dealing with any wiring that's exposed to the elements (such as outdoor lighting or underground wiring), it's important to ensure that the splice is properly sealed and protected from moisture. A professional electrician will have the tools and expertise to do this correctly.

And finally, if you're not sure whether you should call a professional, err on the side of caution and do it anyway. It's always better to be safe than sorry, especially when it comes to electricity. A qualified electrician can assess the situation, provide you with expert advice, and ensure that the job is done safely and correctly.

How To Splice Wires (DIY) Family Handyman

FAQ

6. Frequently Asked Questions about Cable Splicing

We've covered a lot, so let's address some common questions!

Q: Is it always safe to splice cables?

A: Not always. Low-voltage cables are generally safer to splice than high-voltage ones. Always prioritize safety and turn off the power before working on any electrical wiring. When in doubt, call a professional.

Q: What's the best way to insulate a cable splice?

A: Heat shrink tubing is an excellent option. It provides a tight, weatherproof seal that protects the splice from moisture and corrosion.

Q: Can I splice different types of cables together?

A: It's generally not recommended. Different cables have different voltage ratings and impedance, and splicing them together can cause problems. It's best to use the same type of cable for splicing.

Q: What happens if I mess up a cable splice?

A: A bad splice can lead to a variety of problems, including short circuits, fires, and equipment damage. If you're not confident in your ability to splice cables correctly, it's best to call a professional.Hopefully, this has shed some light on the topic! Remember safety first! If you have more questions call a qualified expert, and if you have the proper knowledge, have fun and stay safe!

How To Splice Wires Solder, Crimp, Wire Connectors