Who Else Wants Tips About Why Is PCB Called

Decoding the Mystery

1. Unraveling the Acronym

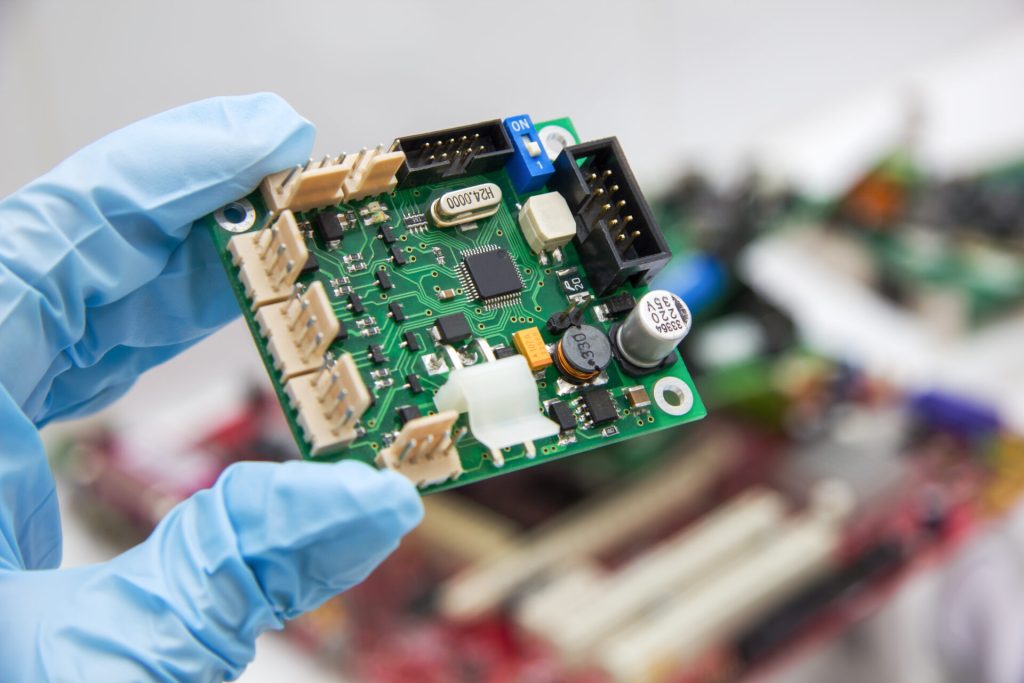

Ever wondered what that green (or sometimes blue, red, or even black!) board inside your electronics is called? Its a PCB! But why PCB? It's a fair question. The answer is delightfully straightforward: PCB stands for Printed Circuit Board. Simple, right? It's an acronym, a handy abbreviation that stuck like glue in the electronics industry. Now, let's delve a little deeper.

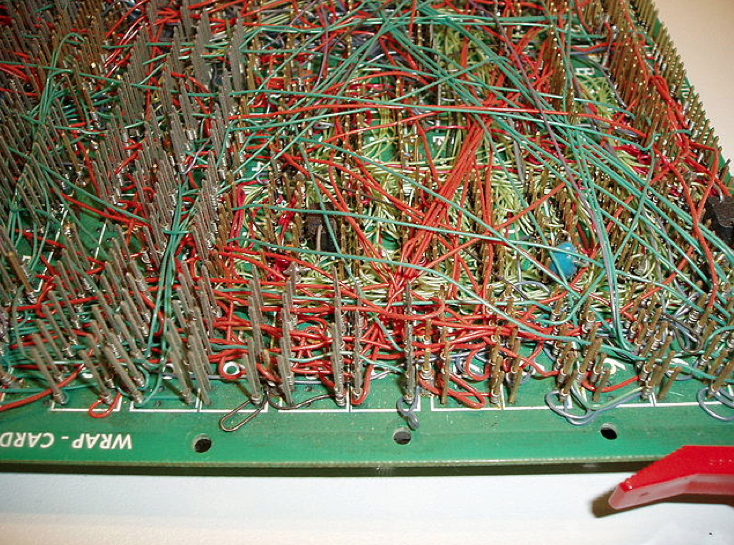

The "Printed" part refers to the manufacturing process. Instead of hand-wiring components, which would be a tedious and error-prone nightmare, circuits are "printed" onto the board using conductive pathways. Think of it like a tiny, intricate road map for electricity. These pathways are typically made of copper and are etched onto the board's surface. It's a far cry from the old days of tangled wires!

The "Circuit" part signifies that the board contains an electrical circuit. This circuit consists of various electronic components, such as resistors, capacitors, and integrated circuits (ICs), all strategically placed and interconnected to perform a specific function. Without this circuit, your phone wouldn't be able to make calls, your computer wouldn't compute, and your toaster... well, it wouldn't toast.

And finally, "Board" simply describes the physical substrate upon which everything resides. It's the base, the foundation, the very essence of the PCB! This board is typically made of a non-conductive material, like fiberglass or composite epoxy, to prevent short circuits and keep everything nice and organized. So, Printed Circuit Board — it perfectly describes what it is and how it's made. Case closed!

PCB Assembly Services, EMS Provider, Cable Wire Cutting Yun Industrial

The PCB Journey

2. A Brief History of PCB Technology

The story of the PCB is a fascinating one, a testament to human ingenuity and the relentless pursuit of miniaturization and efficiency. Before PCBs, electronics were a tangled mess of point-to-point wiring. Imagine trying to troubleshoot that! PCBs emerged as a solution, bringing order to the chaos and paving the way for smaller, more reliable electronic devices.

The early iterations of PCBs were quite different from what we see today. They involved techniques like etching circuits onto Bakelite boards. As technology advanced, so did PCB manufacturing. Multilayer boards, surface-mount technology (SMT), and other innovations revolutionized the industry, allowing for even greater density and complexity.

The evolution of PCB design software also played a crucial role. CAD (Computer-Aided Design) tools enabled engineers to create intricate circuit layouts with precision and accuracy. These tools continue to evolve, pushing the boundaries of what's possible in PCB design and manufacturing. Without these tools, making a complex PCB with thousands of connections would be pretty much impossible.

Today, PCBs are everywhere, from the simplest gadgets to the most sophisticated aerospace systems. They are the unsung heroes of the modern world, silently enabling the technology that surrounds us. So, next time you use your phone or turn on your TV, take a moment to appreciate the humble PCB.

Why PCBs Matter

3. The Significance of PCBs in Modern Electronics

PCBs aren't just about connecting components; they're about enabling entire industries. They are essential for creating reliable, efficient, and cost-effective electronic devices. Their role extends far beyond simple connectivity, encompassing thermal management, signal integrity, and overall system performance.

Consider the complexity of a modern smartphone. It packs an incredible amount of functionality into a tiny space. This wouldn't be possible without advanced PCB technology, including multilayer boards and fine-pitch components. These technologies allow for the creation of incredibly dense and complex circuits, enabling the smartphone's remarkable capabilities. The alternative would be a phone the size of a brick!

PCBs also play a vital role in ensuring signal integrity. As frequencies increase, the design of the PCB becomes critical to prevent signal degradation and ensure reliable communication between components. Engineers carefully consider trace lengths, impedance matching, and other factors to optimize signal performance. It's like ensuring that every message gets delivered loud and clear.

Furthermore, PCBs contribute to thermal management. Electronic components generate heat, and excessive heat can lead to performance degradation and even failure. PCBs can be designed with heat sinks, thermal vias, and other features to dissipate heat and keep components cool. Its all about maintaining the optimal operating temperature for peak performance.

Beyond the Basics

4. Exploring the Diverse World of PCBs

PCBs come in various shapes, sizes, and types, each tailored to specific applications. Single-layer boards are the simplest, with conductive traces on only one side. Double-layer boards have traces on both sides, offering greater flexibility. Multilayer boards consist of multiple layers of conductive traces, separated by insulating layers, allowing for even greater complexity and density. It is like having a multi-story building for electronic components!

Flexible PCBs, also known as flex circuits, are made of flexible materials, allowing them to be bent and folded into complex shapes. These are often used in applications where space is limited or where dynamic bending is required, such as in smartphones and wearable devices. Imagine trying to cram all those components into a phone without the ability to bend the circuit board a little.

Rigid-flex PCBs combine the advantages of both rigid and flexible boards. They consist of rigid sections interconnected by flexible sections, offering a balance of structural support and flexibility. These are often used in applications where both rigidity and flexibility are required, such as in medical devices and aerospace systems.

From consumer electronics to industrial equipment to medical devices, PCBs are ubiquitous. They are the foundation upon which modern technology is built. Understanding the different types of PCBs and their applications is essential for anyone working in the electronics industry — or anyone simply curious about the inner workings of their favorite gadgets.

What Is A PCB Via? Knowledge YouTube

The Future of PCBs

5. Emerging Trends and Technologies in PCB Design and Manufacturing

The world of PCBs is constantly evolving, driven by the demand for smaller, faster, and more efficient electronic devices. Several exciting trends and technologies are shaping the future of PCB design and manufacturing. One major trend is the increasing use of high-density interconnect (HDI) technology, which allows for the creation of PCBs with incredibly fine lines and spaces. This enables even greater component density and improved signal performance.

Another trend is the adoption of advanced materials, such as new laminates and dielectrics, that offer improved thermal and electrical properties. These materials enable PCBs to operate at higher frequencies and temperatures, expanding their capabilities in various applications. Materials science is always pushing the boundaries of what is possible.

3D printing is also emerging as a promising technology for PCB manufacturing. 3D-printed PCBs offer greater design flexibility and the ability to create complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. While still in its early stages, 3D printing has the potential to revolutionize the way PCBs are designed and manufactured. Imagine printing a circuit board on your desktop!

As technology continues to advance, the role of PCBs will only become more critical. From the Internet of Things (IoT) to artificial intelligence (AI) to virtual reality (VR), PCBs will be at the heart of these transformative technologies. The future of electronics is inextricably linked to the future of PCB technology.