Painstaking Lessons Of Info About What Does BOM Mean

10 Types Of BOM And Why They Matter?

Decoding BOM

1. Unpacking the Meaning

Ever stumble across the acronym "BOM" and feel like you've just walked into a confusing acronym convention? You're not alone! It's one of those terms that pops up in various contexts, leaving many scratching their heads. Don't worry; we're here to break it down, showing you it's actually quite straightforward. It's certainly more helpful than a rogue firework!

The most common meaning of BOM is "Bill of Materials." This is where things get interesting, especially if you're involved in manufacturing, engineering, or even just enjoy a good DIY project. Think of a Bill of Materials as a comprehensive ingredients list, but instead of cookies, it's for, say, a bicycle or a smartphone. It lists every single component, raw material, assembly, and sub-assembly needed to create the finished product.

Imagine trying to build a complex piece of machinery without a detailed list of what you need. Chaos, right? A BOM prevents that chaos. It ensures everyone involved in the production process knows exactly what's required, how much of it is needed, and where it should be sourced. No more guessing games or frantic searches for that elusive widget!

Beyond just a simple list, a well-constructed BOM can contain a wealth of information. This might include part numbers, descriptions, quantities, units of measure, and even the cost of each item. This level of detail is crucial for accurate costing, inventory management, and efficient procurement. It's the secret sauce that keeps complex manufacturing operations running smoothly — a sort of manufacturing symphony, if you will.

BOM in the Tech World

2. Navigating the Digital Landscape

But hold on! The story doesn't end there. In the realm of computer science and digital text files, BOM takes on a completely different meaning: "Byte Order Mark." This little critter is a special character, usually placed at the very beginning of a text file, that indicates the encoding used to represent the text. Think of it as a digital accent mark.

Why is this important? Well, computers store text as sequences of bytes. Different encodings, like UTF-8 or UTF-16, use different numbers of bytes to represent characters. A BOM helps software correctly interpret the text, especially when dealing with characters from different languages or alphabets. Without it, you might end up with gibberish instead of a beautifully written article (like this one!).

Imagine receiving an email that looks like a jumbled mess of symbols. Chances are, the email client is having trouble interpreting the encoding. A BOM can help resolve this issue, ensuring that the text displays correctly, regardless of the system or software being used.

Although generally helpful, BOMs in text files can sometimes cause unexpected issues. Some programs, particularly older ones, may not handle BOMs gracefully, leading to errors or unexpected behavior. Because of this, some developers recommend avoiding BOMs in certain situations, opting instead for explicit encoding declarations within the file itself. Its a bit like deciding whether to season your food before or after cooking — both can work, but one might be slightly better depending on the recipe.

Packaging Specification With Bill Of Materials (BOM) Using Solidworks

Beyond the Acronyms

3. Understanding the Nuances

So, what does BOM mean? As you can see, it depends on the context. If you're talking about building something physical, you're probably referring to a Bill of Materials. If you're dealing with computer files, it's likely a Byte Order Mark. Consider the situation to determine the precise meaning. Think of it as like the word "bank" — it could be the side of a river, or where you keep your money. It depends!

The potential for confusion highlights the importance of clear communication. Whenever using the acronym "BOM," especially in a professional setting, it's always a good idea to clarify which meaning you intend. This can save time, prevent misunderstandings, and ensure everyone is on the same page. A little clarity can go a long way!

In the context of manufacturing, the BOM is also closely related to the concept of product lifecycle management (PLM). PLM systems are designed to manage all aspects of a product's life, from design and development to manufacturing and maintenance. The BOM is a critical component of PLM, providing a central repository for all information about a product's components and materials.

Therefore, it's important to consider the broader business and technical landscape when discussing BOMs. Understanding how BOMs fit into larger systems like PLM and enterprise resource planning (ERP) can provide a more complete picture of their importance and value. It's like understanding how a single instrument contributes to the overall sound of an orchestra.

Why BOM Matters

4. The Impact of Accuracy

Regardless of whether you're dealing with a Bill of Materials or a Byte Order Mark, accuracy is paramount. An inaccurate BOM can lead to costly errors, delays, and even product failures. Imagine ordering the wrong parts for a construction project — a recipe for disaster! Similarly, a corrupted Byte Order Mark can render a text file unreadable.

In the manufacturing world, a well-managed BOM is essential for efficient production. It enables businesses to accurately track inventory, manage costs, and ensure that the right materials are available when needed. This, in turn, can lead to improved profitability and customer satisfaction.

In the digital world, a correctly implemented BOM can ensure that text files are displayed correctly across different platforms and applications. This is particularly important for businesses that operate globally or that need to exchange data with partners using different systems. It's all about ensuring that information flows smoothly and reliably.

So, the next time you encounter the acronym "BOM," take a moment to consider the context. Is it a list of materials for building something, or is it a marker for encoding a text file? With a little bit of knowledge, you'll be able to decipher its meaning and understand its significance. And who knows, maybe you'll even impress your friends with your newfound acronym expertise!

The Future of BOM

5. Evolving with Technology

The concept of a BOM is not static. As technology evolves, so too will the way we create, manage, and use BOMs. For example, the rise of cloud-based PLM systems is making it easier for businesses to collaborate on BOMs and share information across different locations. The use of artificial intelligence (AI) and machine learning (ML) is also beginning to automate some aspects of BOM management, such as identifying potential errors and optimizing material selection. Imagine an AI assistant that can automatically detect discrepancies in your BOM and suggest alternative materials based on cost and availability!

In the realm of digital text files, the use of Unicode and UTF-8 encoding is becoming increasingly prevalent. This trend is making BOMs less critical, as these encodings are designed to be self-describing. However, BOMs will likely continue to play a role in certain situations, particularly when dealing with older systems or applications.

The future of BOM will likely involve greater integration with other business systems, such as CRM and supply chain management. This will enable businesses to gain a more holistic view of their operations and make better informed decisions. Imagine being able to track the entire lifecycle of a product, from design to end-of-life, all from a single system!

Ultimately, the goal of BOM management is to improve efficiency, reduce costs, and enhance product quality. By embracing new technologies and best practices, businesses can leverage the power of BOM to achieve these goals and gain a competitive advantage. It's all about staying ahead of the curve and adapting to the changing landscape.

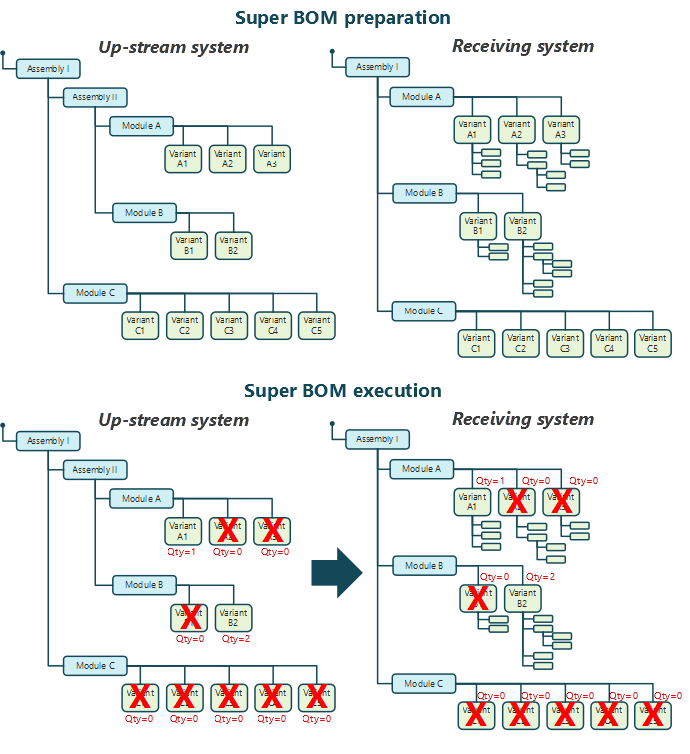

Product Master And BOM Structure For Configuration

FAQ

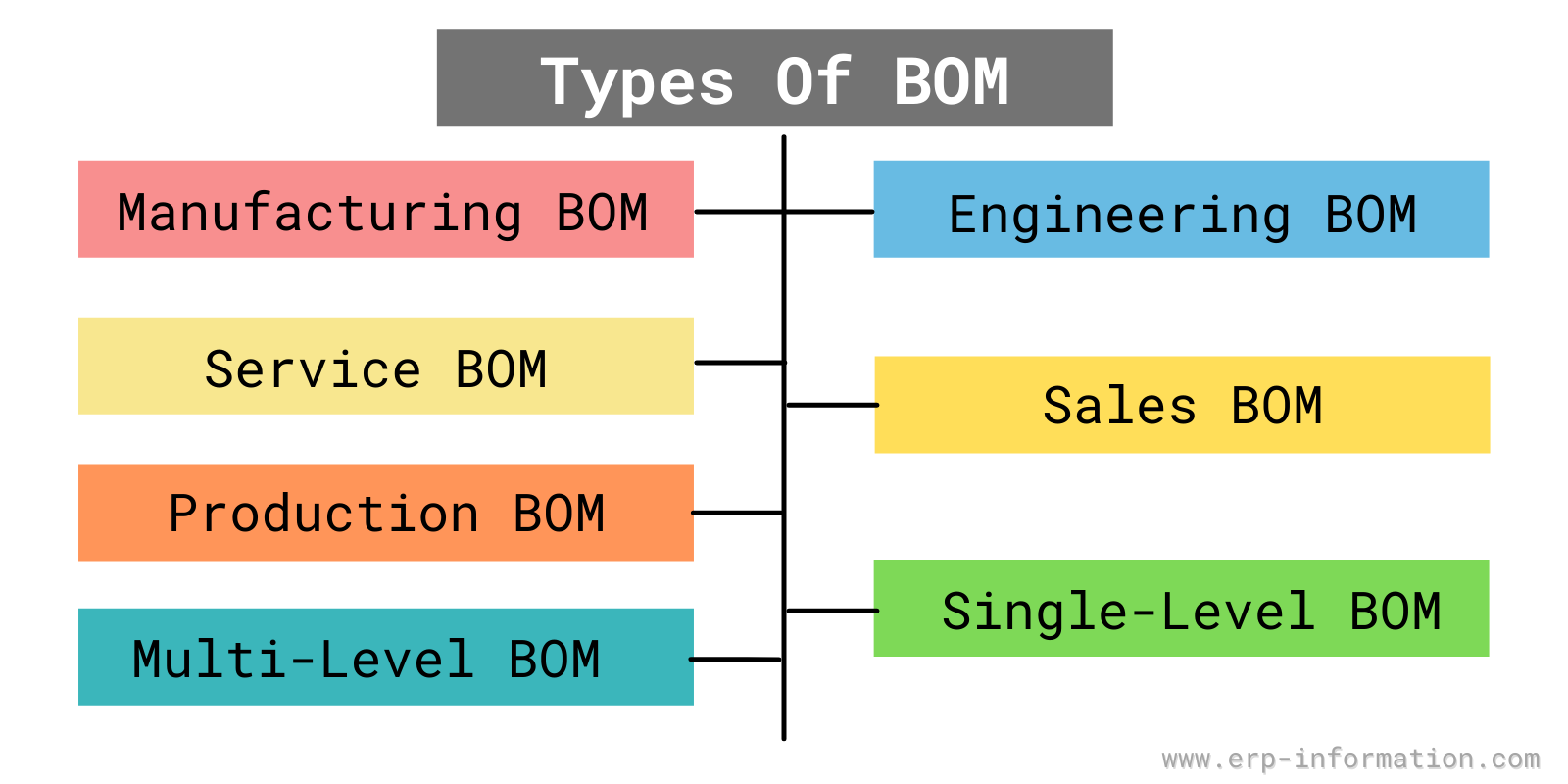

6. What's the difference between a single-level BOM and a multi-level BOM?

A single-level BOM simply lists all the components needed to assemble a product. A multi-level BOM, on the other hand, shows the hierarchical relationships between components, including sub-assemblies. Think of it like a family tree, but for parts!

7. Is a BOM just for physical products?

Not necessarily! While most commonly associated with physical products, a BOM can also be used to describe the components of a software application or even a service. It's all about having a clear and organized list of the elements required to deliver something.

8. What are some common mistakes to avoid when creating a BOM?

Common mistakes include inaccurate quantities, incorrect part numbers, missing components, and outdated information. Regularly reviewing and updating your BOM is crucial to avoid these pitfalls. Think of it as spring cleaning for your manufacturing process!

9. How can I improve my BOM management process?

Consider using a dedicated BOM management software, establishing clear naming conventions, implementing version control, and regularly training your team on best practices. A well-organized BOM is a happy BOM!